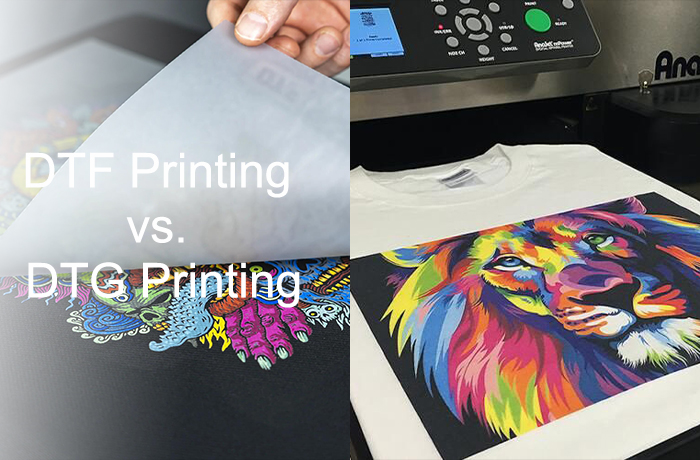

While both procedures have benefits and create high-quality results, understanding their distinctions is essential for making an informed decision depending on your printing requirements. In this post, we’ll look at the distinctions between DTF and DTG printing to help you decide which approach is right for you.

What is DTF printing?

DTF printing, also known as Direct-to-Film printing, is a method of transferring ink from a specialized film onto the surface of a fabric.

DTF printing combines heat and pressure to guarantee that the ink is firmly adhered to the garment, resulting in a long-lasting and brilliant print.

The process of DTF printing?

Design preparation: The desired design is created digitally, ensuring it meets the specific requirements for DTF printing. This includes adjusting colors, resolution, and size.

Film printing: The design is printed onto a specialized DTF film using a compatible printer equipped with DTF ink. The ink is formulated to be compatible with the film and fabric.

Adhesive powder: The ink on the film is coated with a special adhesive powder

Transfer: The film is then placed on top of the garment, and heat and pressure are applied using a heat press machine. This transfers the ink from the film onto the fabric.

Curing: After the transfer process, the garment is typically cured in a heat press or conveyor dryer to ensure the ink fully sets and becomes washable.

What is DTG printing?

DTG printing, also known as direct-to-garment printing, is a type of printing that involves spraying ink directly onto the garment using a specialized inkjet printer.

DTG printing enables for full-color printing, and unlike DTF printing, which employs a film as the transfer medium, ink can be sprayed directly to the garment.

The process of DTG printing?

Pre-Treatment: A specific solution(A pretreatment solution is an aqueous polymeric emulsion that fills the gaps between the fabric’s weaving) is used to prepare the cloth surface for improved ink absorption and adherence.

Curing the solution: Use a heat press to cure the solution.

Printing: DTG printers using water-based inks may print graphics directly onto clothes.

Curing ink: When the ink is applied to the garment, it is cured to ensure the print is long-lasting.

DTF vs. DTG: Key differences

Material compatibility

DTF printing is highly versatile, allowing you to print on a wide range of materials, from cotton to polyester, and even blends. While DTG is excellent for natural fibers like cotton, bamboo, and linen, it may be limited when it comes to synthetic fibers.

Print complexity

DTF is ideal for printing a variety of colorful designs, such as photos, detailed graphics, and long, narrow text. Every detail can be displayed clearly and realistically.

DTG can also print various designs, but since it sprays water-based ink directly onto the fabric, the fabric will absorb some of the pattern, which may affect the design’s accuracy.

Color vibrancy

Both DTF and DTG offer vivid colors, using the CMYK color model. However, DTF uses white ink as the base color, allowing it to produce brighter and more vivid tones, especially on dark or colored fabrics.

DTG printing also offers vibrant colors and requires white as the base color when printing on some dark or colored fabrics.

Durability

Both DTF and DTG are highly durable. Although DTF prints have a plastic feel, they are flexible and can remain intact without easily cracking, even with long-term use.

DTG printing forms a soft print because the ink is absorbed by the fabric, which helps prevent the print from fading during long-term washing.

Comfort

DTF prints are slightly thicker due to the sticky powder binder used in the transfer process, which adds a thin layer of plastic texture to the fabric.

DTG prints are generally softer and more integrated into the fabric, providing a soft touch.

Production speed

DTF printing is faster when producing in large quantities, making it ideal for bulk orders and quick turnarounds. DTG is slightly slower but still works well for small batches.

Choosing the right technique for your needs

When to choose direct-to-film printing

Design Complexity: If your designs include delicate features, gradients, or images, DTF printing’s higher precision and color accuracy may be ideal.

Material Compatibility: DTF printing is the finest option for printing on polyester, nylon, or other synthetic textiles.

Yields and turnaround times: Due to its great efficiency and capacity to handle high-volume manufacturing with minimal setup time, DTF printing is frequently favored for large-scale production runs.

Cost considerations: The cost per print may vary depending on the design’s complexity, quantity produced, and material printed. DTF printing may provide benefits in high-volume production.

When to choose direct-to-garment printing

Design complexity: If your design is simple, you can also use DTG printing. Because the prints are permeable, direct-to-garment printing is ideal for printing larger designs.

Material compatibility: If you are primarily interested in pure natural materials, DTG printing will be more appropriate for you.

Yields and turnaround times: DTG printing excels in printing short runs or one-pieces, making it a good alternative for on-demand or custom orders.

Cost considerations: If you are a one-person shop, DTG printing is more cost-effective for small batch manufacturing and low order volume.

FAQ

Does DTG printing work on dark-colored garments?

Yes, DTF printing may be used to print on dark fabrics. Before applying the color layers, a white base layer is printed on the film. This white foundation layer functions as a barrier, keeping the colors vivid even on dark backgrounds.

Can DTG printing reproduce gradients and fine details accurately?

Yes, DTG printing is excellent at replicating gradients and fine details, making it an excellent alternative for projects requiring complicated artwork and color variations.

Can DTF printing be done on polyester fabric?

Yes, DTF printing works well on polyester fabric.

0 Comments